In today’s global marketplace, products are designed, manufactured, and sold across different regions every day. With this level of scale and diversity, having clear and consistent measurement standards has become more important than ever. That is where size charts come in. These simple but effective tools present measurements, dimensions, and specifications in a way that’s easy to understand. Whether it’s in manufacturing, engineering, e-commerce, or even home improvement, size charts help people compare sizes with confidence and make better decisions.

While most people associate size charts with clothing and footwear, their use goes far beyond that. The same concept can apply to furniture, smartphones, or even machine components—anything that requires accurate sizing. A well-structured size chart eliminates confusion, creates clarity, and ensures that measurements are interpreted the same way no matter the region or unit system being used.

In this beginner-friendly guide, we will cover the essentials of size charts, why they matter, the most common types you will come across, and how to read them effectively. Whether you are shopping online, organizing stock, or handling a technical project, understanding size charts will make the process much smoother.

Why Size Charts Are Essential

Size charts are much more than a simplifying move to the shopping process. Indeed, they are an important aspect of global commerce, production and quality assurance. Consider a factory that manufactures machine parts in large quantities; it would be almost impossible to have consistency unless a good size chart is available. The principle can be applied to the same industries such as construction to consumer electronics.

Here are some key benefits of size charts:

-

Precision and Standardization: Charts ensure everyone uses the same reference measurements, reducing errors.

-

Improved Communication: They make it easier for suppliers, manufacturers and customers to understand product dimensions.

-

Time and Cost Savings: Clear size charts reduce mistakes, product returns, and redesign costs.

Whether for business or personal use, size charts serve as a reliable guide that removes confusion and supports informed decisions.

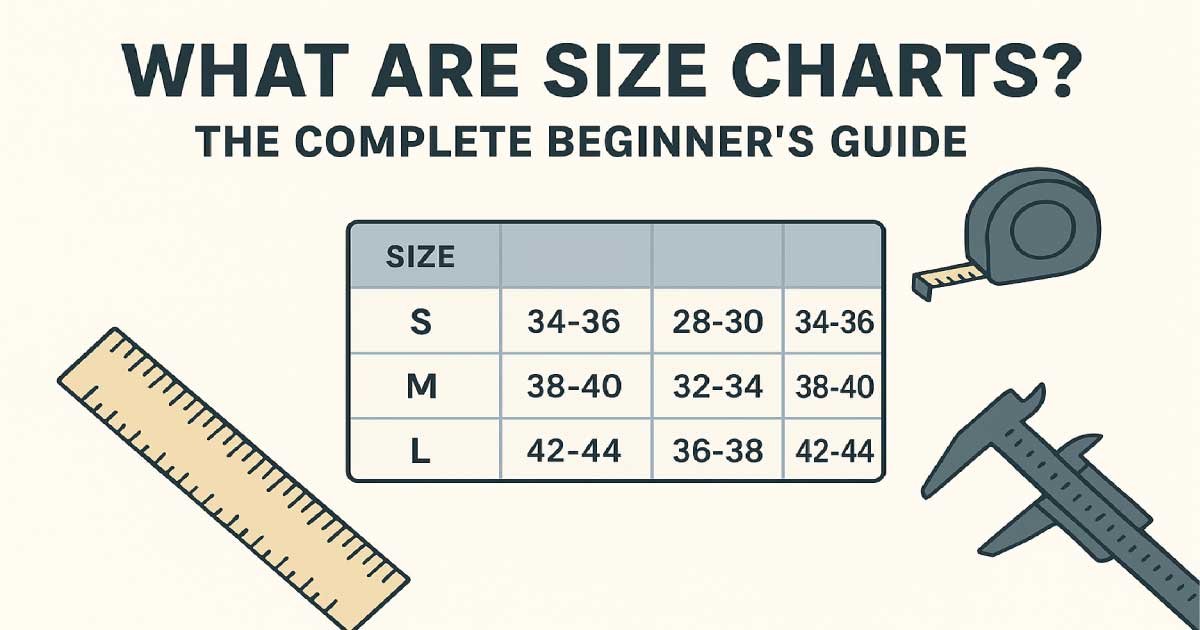

The Core Elements of a Size Chart

While size charts can be adapted for any product or industry, most follow a similar structure. A good chart should include:

Size Labels: These are identifiers, such as numerical codes, alphabetical labels, or descriptive names.

Measurement Units: Size charts typically include measurements in metric units (millimeters, centimeters, meters) or imperial units (inches, feet). Some charts provide both for clarity.

Measurement Categories: These are the specific dimensions being measured, length, width, depth, diameter, weight, volume or capacity.

Standard References: Many industries follow international measurement standards like ISO or ASTM, ensuring consistency across borders.

Example:

| Size Code | Length (cm) | Width (cm) | Weight (kg) |

|---|---|---|---|

| S | 30 | 15 | 0.8 |

| M | 40 | 20 | 1.2 |

| L | 50 | 25 | 1.5 |

This table is not tied to a specific product, it simply shows how measurements are categorized and presented.

Types of Size Charts

While the concept of size charts is universal, their design often depends on the type of product or industry. Below are the broad categories where size charts are commonly used:

Industrial and Manufacturing Charts: For machine parts, tools, and components where tolerances are critical.

E-Commerce and Retail Charts: Used for online product listings to reduce buyer uncertainty and return rates.

Construction and Home Improvement Charts: Provide specifications for furniture, tiles, flooring, and fixtures to ensure accurate installation.

Technical and Engineering Charts: Used by engineers, designers and manufacturers to document precise product specifications.

Scientific and Laboratory Charts: Present measurements for instruments, glassware, and equipment in precise units.

Importance of Measurement Units

One of the biggest challenges with size charts is understanding and converting units. There are two primary systems:

-

Metric System: Used globally; based on meters, centimeters, and millimeters.

-

Imperial System: Primarily used in the United States; based on inches, feet, and pounds.

Having a size chart that includes both units makes products accessible to a global audience. For example:

| Inches | Centimeters |

|---|---|

| 1 | 2.54 |

| 5 | 12.7 |

| 10 | 25.4 |

Charts like this are widely used in design and trade to avoid miscommunication and ensure accurate conversions.

The Role of International Standards

To make sure that measurements are universal, organizations such as the International Organization for Standardization (ISO) are used in the global industries. The ISO standards give guidelines in labeling, measurement unit and product specifications. Indicatively, a bolt produced in Germany, with the ISO standard will not be confused with machinery produced in Japan.

By following these standards, size charts create a universal language of measurements, which is crucial for global manufacturing, engineering, and online retail.

Practical Uses of Size Charts

Here are a few examples of how size charts add value in day-to-day life and professional fields:

E-Commerce: Buyers get accurate information before making a purchase, reducing guesswork.

Engineering: Engineers use charts to maintain precision and consistency in parts and components.

Logistics: Shipping companies rely on product dimension charts to calculate packaging and freight costs.

Interior Design: Charts help customers visualize space and ensure products fit properly in their homes.

A simple chart can save time, reduce costs, and avoid misunderstandings, making it one of the most important reference tools in any industry.

How to Read a Size Chart Correctly

Size charts may look straightforward, but many people still make mistakes when interpreting them. Errors often happen due to misunderstandings about measurement terms, units, or labeling. Learning how to read a size chart properly can save you time, money, and frustration, whether you are shopping online, ordering equipment, or managing a project. Below are the key steps to ensure accuracy.

1. Identify the Size Code or Label

Every size chart begins with a code, number, or label that represents the size category. Understanding these codes is the foundation of reading any chart.

Recognize common labels: In clothing, labels like “S,” “M,” or “L” usually stand for small, medium, and large. In footwear, numbers like “9” or “42” may appear, depending on the region.

Look for industry-specific codes: Technical fields often use alphanumeric codes such as ISO 1234-M6 or DIN numbers. These indicate compliance with international standards.

Check regional variations: A size “10” in the US may differ from a size “10” in the UK or EU. Always confirm which system is being used before making a decision.

Understanding the size label at the start will prevent confusion later on when you compare actual measurements.

2. Understand the Measurement Categories

A size chart is more than just labels, it often lists multiple dimensions that define the product.

Review column headers carefully: Each column may represent length, width, height, diameter, thickness, or even weight. Knowing what each column means is crucial.

Note additional specifications: Some charts include tolerance levels (e.g., ±2 mm), which define acceptable variations in production. This is especially important in engineering or manufacturing.

Match categories to your needs: For example, if you are buying a table, the “height” column may matter most, while for a ring, the “diameter” is key. Focus on the measurements that impact your use case.

By reading measurement categories correctly, you gain clarity on exactly what each size represents.

3. Check the Measurement Units

One of the most common mistakes in reading size charts is overlooking the unit of measurement. A small error in units can cause a major mismatch.

Identify the unit system: Some charts use metric units (millimeters, centimeters, meters), while others use imperial units (inches, feet).

Confirm consistency: A single chart may include both metric and imperial units. Double-check which one applies to your chosen size.

Use conversion tools: If the chart provides only one system, use a reliable conversion table or calculator to translate the measurements into the unit system you’re familiar with.

Being careful with units ensures that what you order or design fits perfectly without costly mistakes.

4. Compare With Your Own Measurements

Finally, always compare the chart values with your actual requirements.

Take accurate measurements: Whether it’s body size, furniture space, or machine parts, measure carefully using the correct tools (e.g., tape measure, calipers).

Cross-check with the chart: Match your numbers with the size chart values to find the best fit. Always allow for tolerances or slight variations.

Think about usability: For clothing, comfort matters; for tools or machinery, precision matters. Select the size that best serves your purpose, not just the closest match.

This step confirms that the chosen size meets your exact needs before you make a purchase or place an order.

Reading a size chart correctly may seem simple, but overlooking labels, measurement categories, or units can lead to costly errors. By carefully identifying the size code, understanding each measurement category, checking units, and comparing with your own measurements, you can select the right size with confidence. Whether you are shopping online or working on a technical project, these steps will help you avoid mistakes and make smarter decisions.

Common Mistakes When Using Size Charts

Even experienced professionals sometimes misread size charts, leading to costly errors. Here are some frequent mistakes to avoid:

-

Ignoring Units of Measurement: Confusing centimeters with inches or millimeters can cause significant problems in industries that require precision.

-

Overlooking Tolerances: Many charts specify acceptable measurement ranges. Skipping this detail can lead to parts that don’t fit.

-

Assuming Universal Standards: Not all size charts follow the same conventions. Always check for notes on standards (ISO, ASTM, or local guidelines).

-

Using Approximate Measurements: Rounding up or down may work for some retail items, but in technical fields, precision is critical.

A well-structured size chart is a tool for accuracy, but it only works if you approach it carefully.

How to Create a Professional Size Chart

You can use a trustful online store, run manufacturing processes, or publish technical papers, in any case; setting up transparent and correct size chart may enhance efficiency.

1. Start With Accurate Measurements

The foundation of any size chart is accurate data. Always use reliable tools such as calipers, measuring tapes, or laser meters depending on the product. Double-check measurements to avoid mistakes. Even small inaccuracies can cause confusion, returns, or customer dissatisfaction. Precision builds trust and ensures your chart is dependable.

2. Choose the Right Units

Units often cause confusion when charts are read globally. To avoid this, include both metric and imperial values. For example, show measurements in centimeters alongside inches. This simple step makes charts easier to understand and more user-friendly, reducing errors and saving customers from doing their own conversions.

3. Organize Measurements Logically

A good size chart should flow naturally, helping readers find what they need quickly. Arrange dimensions in an order that makes sense, such as length, width, depth, then weight. For clothing or complex products, consider multi-level tables. Logical organization reduces guesswork and enhances overall clarity for the end user.

4. Use Clear Labels and Notes

Clarity is key when creating size charts. Labels should be specific, such as “waist circumference” or “product height,” rather than vague terms. Add footnotes for tolerances or additional guidance, like “±0.5 cm.” Helpful notes reduce misinterpretation, ensuring buyers and professionals alike understand exactly what each number represents.

5. Make Charts Visually Easy to Read

Even accurate data loses value if presented poorly. Use clean formatting, consistent fonts, and clear headings so charts don’t feel overwhelming. Adequate spacing makes numbers easier to scan. For digital platforms, opt for responsive tables that adapt to mobile screens. A visually simple chart improves usability and professionalism.

6. Follow Industry Standards

Whenever possible, align your measurements with recognized industry standards. Standards provide consistency and credibility, whether you’re selling clothing, electronics, or machine parts. Following them also helps in international markets, where different regions may have specific expectations. By adhering to these norms, your size charts become both professional and trustworthy.

Conversion Tables: Bridging the Gap Between Systems

Size charts can be confounded most with measurement conversions. In the case of a 25 cm object, say, 9.84 inches, and a 1-inch screw that is 25.4 mm in length. Values can be misinterpreted by the users without a trusted system of conversion.

Here’s a simple conversion reference:

| Measurement | Metric | Imperial |

|---|---|---|

| 1 inch | 2.54 cm | 1 inch |

| 1 foot | 30.48 cm | 12 inches |

| 1 cm | 10 mm | 0.39 inch |

| 1 meter | 100 cm | 39.37 inches |

Including quick conversion charts next to your size tables makes your documentation user-friendly, especially for international audiences.

The Role of Size Charts in Different Industries

Let’s explore how size charts create value across a variety of industries beyond retail.

1. Manufacturing and Engineering

In manufacturing, accuracy is everything. Size charts provide exact details like diameter, thread pitch, or tolerance, ensuring parts fit seamlessly into machines. For example, a bolt chart helps engineers select the right component. Without these references, mismatched pieces could lead to costly errors, equipment failure, or safety risks.

2. Logistics and Supply Chain

In logistics, size charts simplify planning and reduce costs. They help determine shipping expenses, packaging needs, and warehouse storage. Charts for pallets, containers, and packages ensure space is used efficiently while protecting goods in transit. By relying on accurate dimensions, companies streamline operations and improve overall supply chain performance.

3. Healthcare and Medical Equipment

For healthcare, size charts directly impact patient safety. Medical devices such as syringes, implants, or diagnostic tools come in standardized sizes. Charts guide doctors and technicians to select the right fit quickly, avoiding complications. Accuracy here is not just convenient, it ensures treatments are effective and patients receive proper care.

4. Home and Interior Design

Interior designers and architects rely heavily on dimension charts. Whether planning furniture layouts or installing appliances, these charts confirm everything fits properly in a given space. Without them, costly mistakes or awkward arrangements could occur. Accurate sizing helps professionals create functional, aesthetically pleasing spaces tailored to each client’s needs.

5. Industrial Safety Equipment

Safety equipment only works when it fits correctly. Helmets, gloves, and harnesses must meet strict size standards to protect workers. Size charts provide clear guidelines for selecting the right gear, reducing risks on the job. By ensuring proper fit, they safeguard employees and promote a safer workplace environment overall.

Why Size Charts Build Trust Online

Online shoppers and professionals nowadays rely on the product descriptions in the digital era. Detailed size chart generates trust as it demonstrates that the seller or producer attaches importance to precision. Transparent sizing also decreases the possibility of a conflict or adverse feedback.

-

For Sellers: A clear chart demonstrates professionalism and reduces customer support inquiries.

-

For Buyers: Charts eliminate uncertainty, making it easier to purchase confidently.

-

For Global Markets: Accurate sizing enables companies to cater to multiple countries without confusion.

Whether you are a small business or a large manufacturer, a well-structured size chart acts as your silent salesperson, answering sizing questions before they are even asked.

Best Practices for Interpreting Size Charts

-

Always check the measurement reference point. For example, a “length” column could refer to total length, inner length, or usable length.

-

Look for tolerances (± values) to understand acceptable deviations.

-

Use conversion tools or calculators if the chart doesn’t include both metric and imperial units.

-

Verify if the chart is based on industry standards (ISO, ASTM, ANSI, or regional equivalents).

-

When in doubt, reach out to the manufacturer or supplier for clarification.

Appropriate interpretation makes sure that size charts can be used as intended: to simplify the multifaceted measurements and minimize human error.

Global Measurement Standards and Their Role in Size Charts

Compliance with international standards of measurement is one of the most significant points of size chart creation and interpretation. Without a universal structure, each producer or vendor would develop charts according to their definitions, would cause confusion, waste of resources and expensive mistakes.

Here are some of the most widely recognized standards:

1. ISO (International Organization for Standardization)

ISO drafting and publication of global measuring and sizing standards of almost all industries. Indicatively, the ISO standards determine the size of the bolts, screws, medical equipment, and consumer products, which are compatible with the standards used in other countries. A size chart that has been made in compliance with ISO ensures that buyers and suppliers are certain that dimensions are correct and globally interpreted.

2. ASTM International

ASTM International is dedicated to the creation of technical standards in such industries as construction, materials testing and manufacturing. ASTM standards do not only define product specifications, but also test procedures to check those measurements. The charts that are ASTM-based assist in assuring the safety and quality of products.

3. ANSI (American National Standards Institute)

ANSI develops U.S.-based standards that often complement ISO guidelines. Size charts aligned with ANSI standards are common in engineering, electrical equipment, and industrial design.

4. Regional and Industry-Specific Standards

Certain industries have their own measurement frameworks:

-

DIN (Germany): Focuses on engineering and manufacturing standards.

-

BSI (UK): British standards are widely referenced for construction and product design.

-

JIS (Japan Industrial Standards): Critical for electronics, automotive parts, and machinery.

By aligning size charts with recognized standards, companies ensure that their products are universally compatible, reducing risks in global trade and manufacturing.

The Evolution of Size Charts

Size charts are not new but are changing with technology on the way they are created and used. Manuals, catalogs, or labels are traditionally printed on paper and served as size charts, although in the modern world they can be found on the Internet, embedded in online shopping software, or even in design software.

Here are some trends shaping the future of size charts:

1. Digital Tools and Automation

Size charts can be automatically created using data on modern tools. As an example, product information management (PIM) software is capable of extracting measurements out of a database and producing standardized tables to be used by websites and marketing materials.

2. Interactive Size Guides

E-commerce platforms increasingly use interactive charts. Instead of static tables, these tools allow customers to enter their measurements, and the system recommends the best size. This improves user experience and reduces guesswork.

3. Augmented Reality (AR) and 3D Visualization

Virtual measuring tools are now available in some companies which involves a smartphone camera to see the space of a product in a customers house. This is particularly a trend that can be applied in furniture, home improvement and interior design.

4. AI-Powered Recommendations

Artificial intelligence is making size charts smarter. By analyzing customer purchase history and returns, AI can suggest size adjustments or even customize size charts for specific regions and demographics.

Why Every Industry Needs Standardized Size Charts

Although many people associate size charts only with clothing or consumer products, their role extends far beyond retail. Accurate charts provide benefits across multiple sectors:

-

Manufacturing: Inconsistent measurements can halt production or cause large-scale recalls. Standardized charts ensure smooth assembly and consistent quality.

-

Healthcare: Properly sized medical tools, implants, and devices save lives. Precision is critical in medical manufacturing.

-

Construction: Builders and architects rely on size charts to confirm that every component fits within a structure’s specifications.

-

Logistics and Packaging: Freight companies use charts for package dimensions and weight classes to optimize transportation.

The takeaway is clear: size charts are not just about convenience, they are about accuracy, safety and efficiency.

How to Choose or Create the Right Size Chart for Your Needs

Whether you are a business owner, engineer, or consumer, selecting or creating the right size chart starts with clarity and standardization.

-

Define the Purpose: Identify whether your chart is for internal manufacturing, retail, logistics, or another purpose.

-

Collect Accurate Data: Always measure using precise tools and repeat measurements to confirm accuracy.

-

Decide on Unit Systems: Choose metric, imperial, or both based on your target audience.

-

Use Standard Templates: Adopt ISO or industry-specific templates to ensure your chart is easy to understand.

-

Add Context and Notes: Include tolerances, application instructions, and other helpful information.

-

Test for Usability: Share your chart with colleagues or customers to ensure it’s intuitive.

The more effort you put into clarity, the fewer errors and misunderstandings your users will face.

Quick Tips for Interpreting Complex Size Charts

Some charts, especially those in technical or industrial fields, can look intimidating. Here are practical tips for breaking them down:

-

Focus on Column Headers: These contain critical information about what each measurement represents.

-

Understand Abbreviations: Technical size charts often use symbols or shorthand (e.g., OD for outer diameter, ID for inner diameter).

-

Look for Standard Codes: If the chart references ISO or ASTM codes, research them to understand exact requirements.

-

Double-Check Tolerances: Precision engineering often uses ± values that indicate acceptable measurement variations.

-

Use Conversion Tools: A calculator or software can help interpret measurements quickly and avoid manual errors.

The Future of Size Charts

The globalization of industries only demands the universal size standards. Businesses are already testing cloud-based databases where suppliers, retailers and customers can have access to the same sizing information on-the-fly. This is what to look forward to in the future:

-

Global Standardization: ISO and other international bodies will continue to harmonize sizing systems, reducing confusion.

-

Automated Sizing: Products may soon include QR codes or NFC chips that link to live digital charts.

-

Personalized Recommendations: AI will deliver size suggestions based on user preferences, regional trends, and product availability.

-

Sustainability Impact: By improving size accuracy, companies can reduce waste caused by returns, replacements, or defective products.

Size charts are evolving from static tables into intelligent tools that enhance decision-making and customer experience.

Conclusion: Size Charts as a Universal Language

Size charts can be viewed as very basic, yet, this is one of the strongest items in the modern interconnected world. They help fill the communication gaps between industries, countries and customers to make sure that products are of the expected standards and quality. Having a properly organized size chart will save time and create confidence whether you are an engineer going through specifications, a business owner cataloging on the internet, or a consumer making a purchase decision.

By putting money on correct measurements, keeping up with global standards, and embracing today digital tools, one can turn the size charts into a global and universal language of accuracy. To businesses they improve trust and cut down costs; to consumers, they ease the decision-making process.

With a market that is dependent on speed, quality and accuracy size charts will still be a pillar of good communication. You not only make smarter choices or designs by knowing and using them efficiently, but also help make the world a better place where measurements become no longer a source of confusion,

Also Read:

FAQs:

What is a size chart used for?

A size chart is a reference guide that shows product measurements such as length, width, height, or weight. It helps customers, manufacturers, and suppliers understand exact dimensions before making a purchase or producing items. By using a size chart, people can avoid confusion, ensure compatibility, and reduce costly mistakes. These charts are especially valuable in industries like clothing, furniture, engineering, logistics, and healthcare.

Why are size charts important in online shopping?

Size charts are crucial in online shopping because customers cannot physically try or measure products. A clear chart reduces guesswork, increases confidence, and lowers the risk of returns or exchanges. For clothing, it ensures a better fit; for furniture or equipment, it confirms proper dimensions. Retailers that provide accurate size charts build trust with customers and often experience higher satisfaction rates and fewer refund requests.

How do I read a size chart correctly?

Reading a size chart involves checking size codes (like S, M, L, or numerical values), understanding measurement categories (length, width, depth), and verifying the unit system (metric or imperial). Always compare the listed values with your own measurements. For technical items, note tolerances or standards such as ISO or ASTM. Following these steps ensures you select the correct size and avoid mismatches in your purchase.

What is the difference between metric and imperial size charts?

Metric size charts use measurements such as millimeters, centimeters, and meters, while imperial size charts rely on inches and feet. The metric system is widely used internationally, while the imperial system is still common in the United States. Misunderstanding units can lead to costly errors, especially in engineering, construction, or global trade. Many professional charts now include both systems for clarity and global accessibility.

How do size charts reduce product returns?

Size charts reduce returns by providing customers with clear, accurate dimensions before purchase. When buyers know exactly what to expect, they are less likely to receive items that don’t fit or meet requirements. This is particularly effective in e-commerce, where fit and size are common reasons for dissatisfaction. Retailers who publish detailed charts often experience fewer complaints, lower return rates, and improved overall customer loyalty.

What industries use size charts besides clothing?

Size charts are used in many industries beyond fashion. In manufacturing, they specify machine parts and components. Logistics companies rely on them for packaging and shipping dimensions. Healthcare professionals use standardized charts for syringes, implants, or equipment. Interior designers need them for furniture fitting, while safety industries depend on charts for helmets, gloves, and harnesses. Essentially, any field requiring precise measurements benefits from size charts.

How can businesses create effective size charts?

To create an effective size chart, businesses should start with accurate measurements using reliable tools. Including both metric and imperial units ensures global usability. Organize data clearly, label each dimension, and provide notes for tolerances or standards. Visual clarity matters, so clean layouts with easy-to-read tables are best. Aligning with ISO, ASTM, or ANSI standards further builds trust. Ultimately, a well-structured chart improves efficiency and customer satisfaction.

I’m Engineer Hassan, a professional engineer with deep experience in measurements, design accuracy, and product sizing. Through Size Helper, I share research-based size guides for household items, fashion, and sports to help users make confident decisions. Every article is written with real expertise, verified data, and a commitment to quality and user trust.